Pilot Wire Communication is most important for secured operation of AC EV Chargers.

1.0: Introduction: EV Charging technology is quite advanced as Electric Vehicle in the current form is quite new. This technology is basically used to charge Electric Vehicle Batteries. It’s highly important to take care of the Safety factors of Battery during charging as any irregularities can cause the batteries to catch fire. Lithium-ion battery cells combine a flammable electrolyte with significant stored energy, and if a lithium-ion battery cell creates more heat than it can effectively disperse, it can lead to a rapid uncontrolled release of heat energy, known as ‘thermal runaway’, that can result in a fire or explosion.

1.1: The EV Charging technology takes care of the safety of the Li-Ion Battery and provides safe & user-friendly charging of the EV Batteries through effective pilot wire communication. To understand it better, we have to understand the difference between “communication” and ‘controls’ in EV Charging. In EV Charging, the EVSE (the charger) communicates some of its important parameters to the Electric Vehicle before and during the charging process. EVSE never controls anything in an electric vehicle during charging.

In case of AC charging, the EVSE will communicate with the EV through pilot wire communication and when permitted by the EV, it will just deliver the required AC Power to the “On-Board Charger” of the EV. Charging start, charging operation and charging stop will be completely controlled by the EV. The EVSE will not control anything of “On-Board Charger” of the EV. However, EVSE can STOP Charging in case of any problem.

1.2: Let’s see how EV Chargers normally charges an electric vehicle?

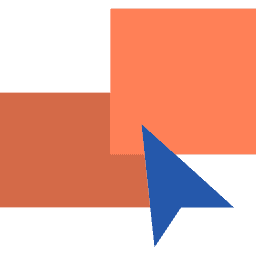

If you see Fig-1 closely, you’ll be able to find out how AC & DC Chargers will function.

All electric vehicles are manufactured with a built-in “On-Board Charger”.

The AC Charger connector is Type 2 (often referred to as Mennekes – Company that designed it).

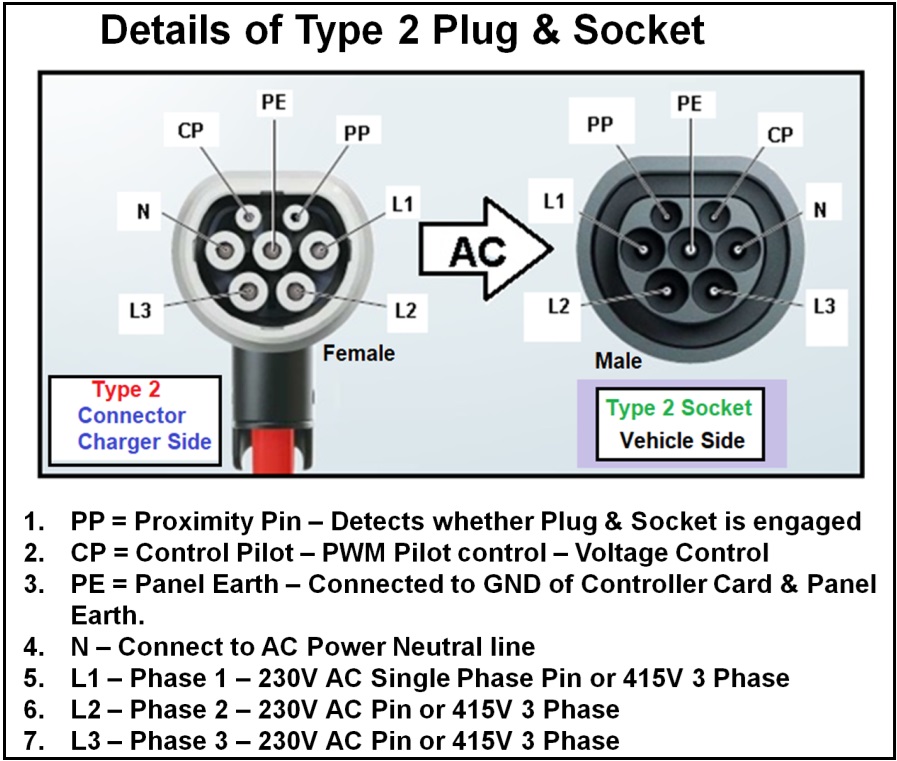

1.3: Let’s find out Type 2 Connectors Pinout and relevant details:

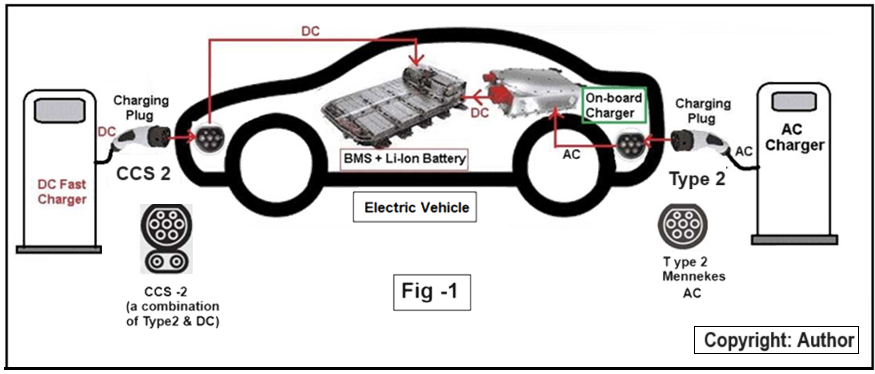

Type 2 Connector is a 7 Pin Connector. Male Socket will be built-in Electric Vehicle and Female Plug will be in the Charger with trailing cable (See Fig-1A below).

Fig – 1A

Fig – 1B

Fig – 1C

Fig-1C above describes the function of each pin in Type 2 Connector.

Out of 7 Pins 3 Pins – PP, PE & CP are used to establish digital communication between charger and EV and the other 4 Pins – N, L1, L2 , L3 are used to transfer AC Charging power to the EV.

PE is panel earth and connected to GND (- common) of 12V SMPS or in other words PE acts as the reference pin for CP & PE.

The DC 12V SMPS supplies power to all cards.

1.4: The On-Board Chargers are built to accept AC Power at the input which will be converted to suitable DC Power to charge the Li-Ion Battery of the electric vehicle. To restrict weight increment of the electric vehicle, the On-Board Chargers have a limited maximum capacity of 22kW (32A maximum current capacity). As the name implies, AC Chargers delivers AC voltages to the On-Board Charger and so the AC Charger capacity can be maximum 7.4kW in 230V Single Phase AC and 22kW (7.4 X 3) in 230V Three Phase AC.

1.5: EVSE communicates the following parameters to EV: (1) Maximum available current during charging and this is communicated to EV before the charging could actually begin and also throughout the charging process. AC Charger performs a handshake with the EV before charging and this communication is called the pilot wire communication. The communication is done through PWM signal which is generated by the EVSE. The specification of the PWM is standardized and quite inflexible. PWM Pilot Wire Communication: Frequency = 1kHz +/- 0.1% Duty Cycle = Maximum Current Capacity / 0.6 +/- 0.1% You can see that the tolerance is very tight and has to be strictly maintained by the EVSE. But why the tolerance is so tight? This question can be answered only when we will go through the charging process:

1.6: Let’s see an actual AC Charging process:

STEP-1: Plug & Socket Not Engaged

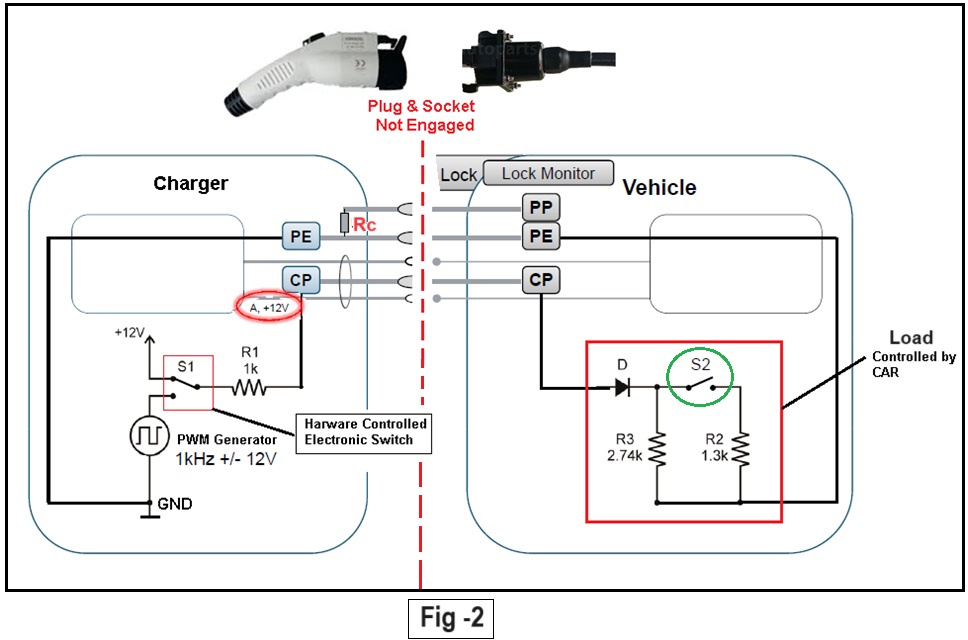

Fig-2 above is an equivalent circuit drawn to understand the theory behind electric vehicle charging.

In Fig-2, the Left Block is the Charger or EVSE equivalent circuit and the right block is the Vehicle or EV equivalent circuit.

The Pilot Wire communication is performed by 3 connections – PP, PE & CP of the Type 2 Plug & Socket.

PE is connected to Earth of EVSE. PE of EV cannot be connected to Earth as it stands on insulated tires and so EV gets the Earth connection through EVSE when Plug is engaged.

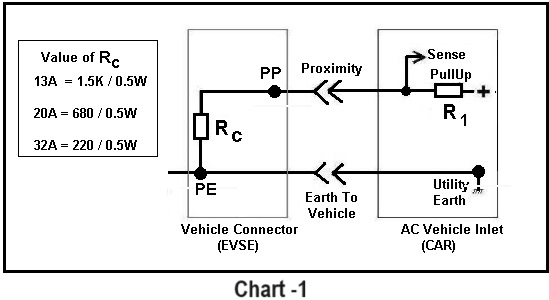

PP is the proximity pin. The EV PE pin is connected to Earth (GND) via a resistor Rc. The value of Rc is standardized as per EVSE Current capacity (shown below).

CP is the control pilot pin through which EVSE and EV Pilot Wire Communication is performed.

The left hand block of EVSE has a hardware controlled switch S1.

The right hand block of EV has a hardware controlled switch S2.

The red square block is the equivalent Load that EV will control through CP pin as and when required. When switch S2 is open, the equivalent load will be 2.74k Ohms and when Switch S2 is closed, the equivalent load will be reduced to 882 Ohms.

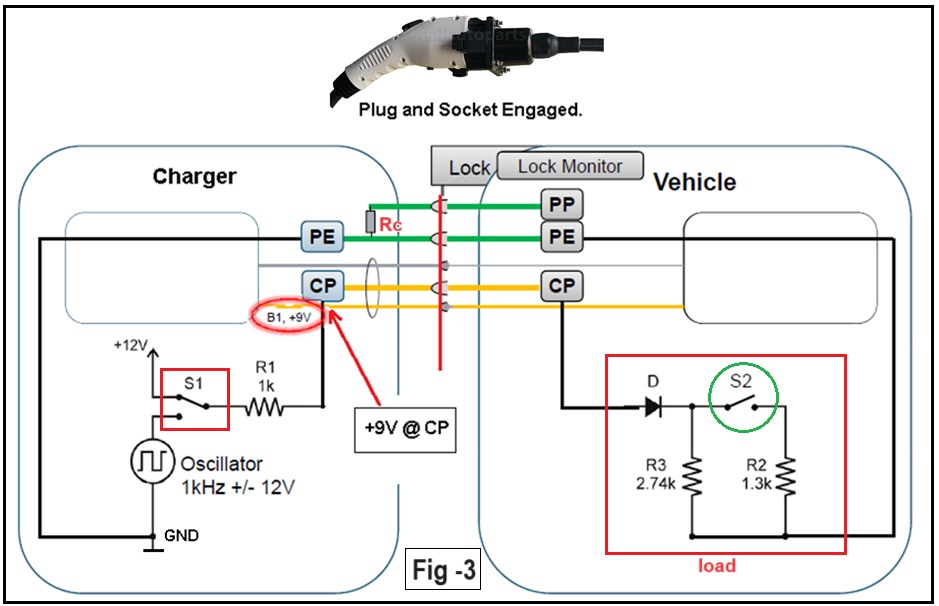

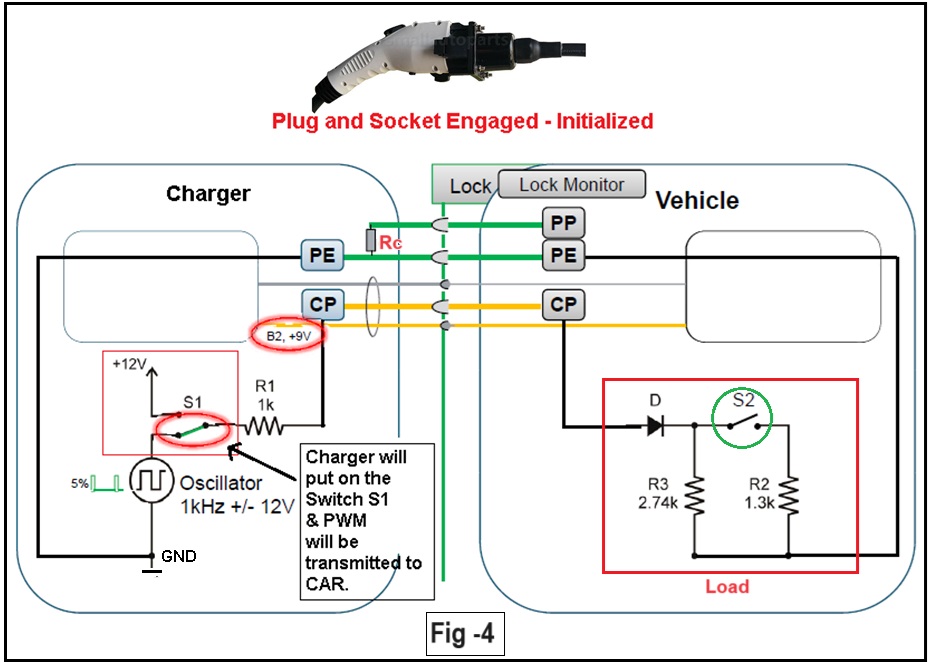

STEP-2: PWM – Pilot Control – Plug & Socket Engaged

The System is initialized & EV will check whether Plug is Engaged properly through Rc.

Now, PP of EV is connected to Earth (GND) of EVSE through Rc. PE & CP of both EV & EVSE are connected.

In STEP-1, the voltage at CP pin of EVSE was +12V DC as Plug was not engaged.

When Plug is engaged in STEP-2, CP of EVSE will be connected to GND through 2.74k Ohms and this will reduce the Voltage at CP of EVSE to +9V DC. The EVSE will measure this voltage and understand that the Plug is engaged.

But, how the EV will know that the Plug is properly engaged or not?

Well, EV will send a small current through Rc and measure the voltage drop across Rc to find out that the Plug is properly engaged. Rc serves a dual purpose, it ensures that plug is properly engaged and when EV will measure the value, it will also know approximately the range of maximum current capacity of the charger (See Chart-1).

STEP-3: PWM – Pilot Control – Plug & Socket engaged.

Charger will make S1 ON and PWM Signal will be transmitted to EV.

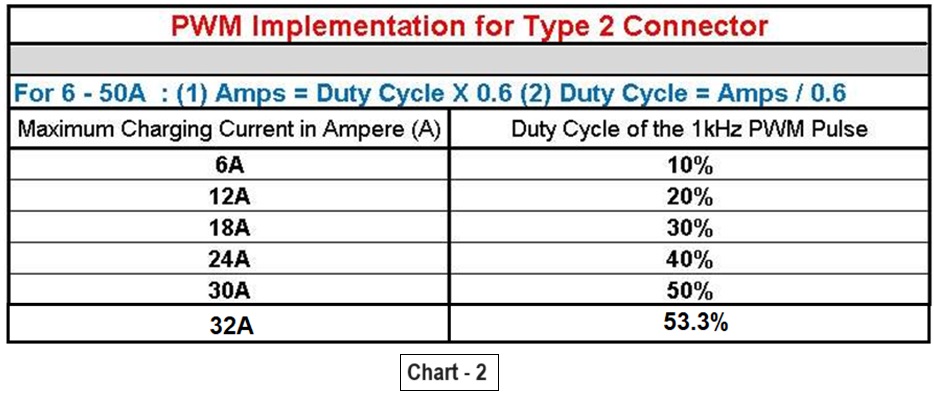

As soon as the Charger finds that voltage at CP is +9V DC, it will understand that the Plug is properly engaged and Put on the Switch S1 to transmit PWM Signal to the EV. The EV will read this PWM Signal to find out the Maximum Charging Current Capacity of the Charger. The EVSE has to generate accurate PWM signal transmission to EV. Here’s the Standard:

Duty Cycle of PWM Pulse is measured % , here is a simple formula to find the Duty Cycle:

Duty Cycle = Maximum Current / 0.6 Example = Duty Cycle for 32A Current = 32/0.6= 53.3%

EV will read the received PWM Signal to find out whether it’s compatible to its own “On-Board Charger”.

Let’s take an example to understand these criteria:

Say, the EVSE sends a PWM Signal of Frequency 1kHz @53.3% Duty Cycle. This means the EVSE can transfer a charging current of maximum 32A and not more (See Chart-2).

Now, the EV will find out whether its “On-Board Charger” is compatible to 32A or not.

If it is compatible, then the EV will take the next Step in charging.

1.7: Now here is an important feature of EV Charging: The EV can use the available 32A or anything less than that, but never more than 32A as the EVSE will trip at 32A Maximum current.

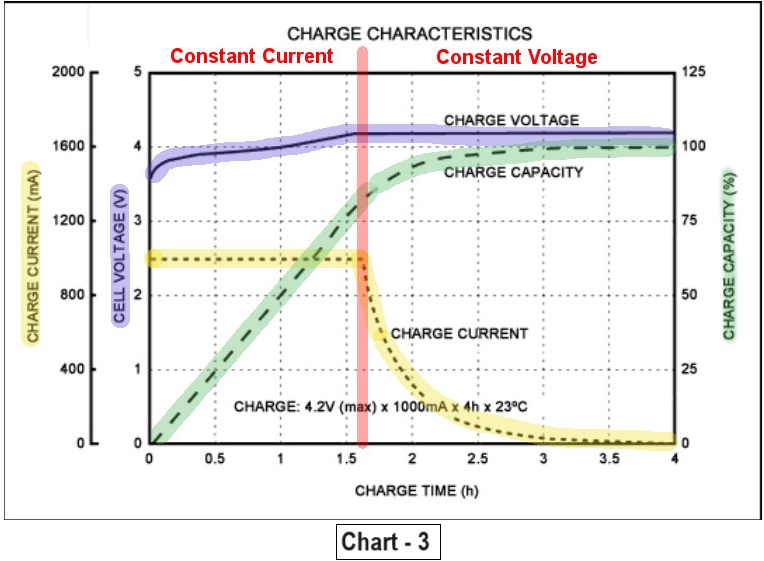

1.8: The EV charges its Battery through “On-Board Charger” and the algorithm is CC-CV as shown below (Chart-3):

This CC-CV Charging algorithm is a built-in feature of the “On-Board Charger” and not controlled by the EVSE. The “On-Board Charger” will reduce the current when Constant Voltage stage will arrive. So, the EV decides how much current to draw from EVSE subject to the Maximum Current capacity of the EVSE.

“EVSE will never control the current, it will only communicate to the EV through PWM signal by Pilot Wire Communication the Maximum Current Capacity.”

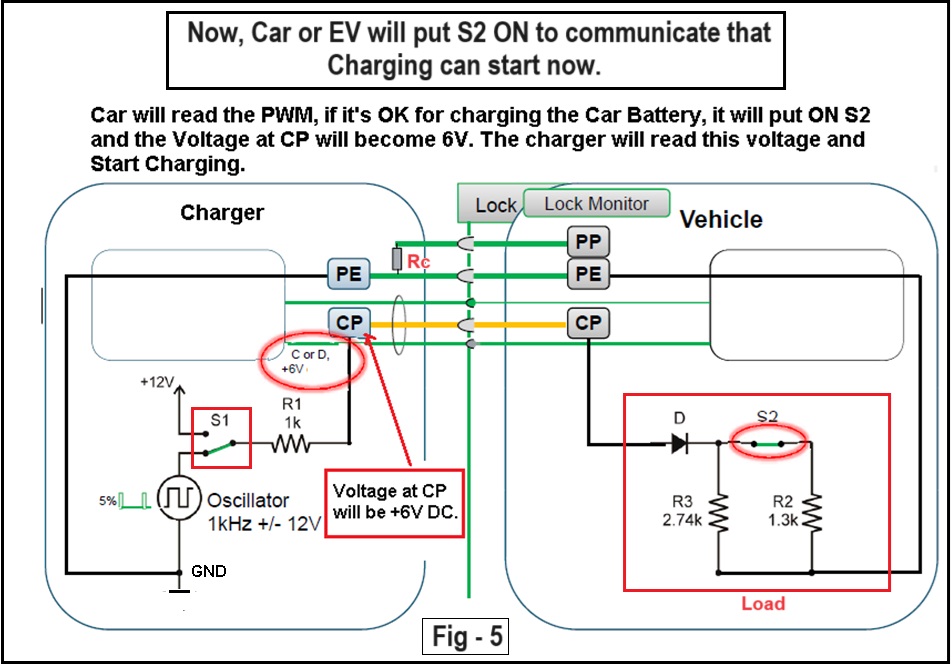

The EV will read the PWM Signal and if it’s compatible to its “On Board Charger”, it will make Switch S2 – ON. As soon as S2 is ON, the load at CP will reduce to 882 Ohms. This will reduce the Voltage at CP to +6V DC. The EVSE will read the voltage and understand that EV has given permission to start the charging process. So, EVSE will connect the AC Voltage to the EV and Charging will start.

The “On Board Charger” of EV will carry out the charging through CC-CV method. This means that the charging is entirely controlled by the EV only. As soon as the charging is over, EV will open S2 and the Voltage at CP of EVSE will become +9V DC again. EVSE will understand that charging is completed and it will provide a ‘Charge Complete” signal to the user. The user will now release the Charging Plug to detach the EV from EVSE.

If the PWM Signal transmitted by the EVSE fluctuates more than the allowable tolerances, then EV will STOP Charging and wait for the PWM to stabilize or if it’s not stabilized within 30 seconds, it will abort charging.

So, in practice, you have to generate a stable PWM Signal within the allowable tolerances and this is definitely a tough job. This is the only problem faced by many EV Charger manufacturers. You may click the following link to find out how “Elec Design Hub” has used ESP32 to generate a highly steady and accurate PWM Signal for Pilot Wire Communication.

Click: Home EV Charger – 7.4kW-Type 2 Complete Design Package

Click here to get your EV Charger Front Panel Overlay design: